|

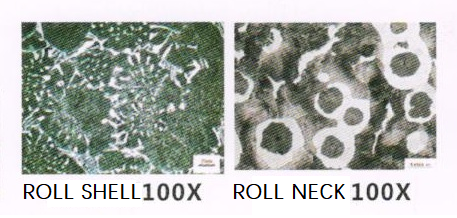

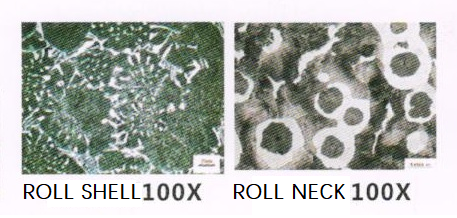

The organizational structure and properties of HSS rolls

The type of HSS roll’s carbide

The one of significant tendency of roll development is widely applying alloy in rolls material to form different kind of carbide, the kinds, distribution and quantity of carbide decide the quality of rolls.

|

Rolls material

|

Main type of carbide

|

Carbide shape

|

Microstructure carbide hardness(HV)

|

|

HSS Rolls

|

MC

|

VC

|

Granular

|

2800

|

|

TiC

|

Granular

|

3200

|

|

NbC

|

Granular

|

3000

|

|

WC

|

Granular

|

2400

|

|

M2C

|

Mo2C W2C

|

Rod-like Feathery

|

2000

|

|

M6C

|

Fe3W3C

|

Herringbone

|

1500-1800

|

|

HCI Rolls

|

M7C3

|

Cr7C3

|

Chrysanthemum

|

1200-1600

|

|

M23C6

|

Cr23C6

|

Granular(twice)

|

1200

|

|

ICDP Rolls

|

M3C

|

Fe3C

|

Reticular

|

840-1100

|

mechanical property of HSS rolls:

|

Rolls material

|

Carbide

|

Matrix Hardness(HV)

|

Surface HSD

|

Tensile Strength

MPa

|

Compressive Strength

MPa

|

Fracture Toughness Mpa.m1/2

|

Compare

Wear Resistance

|

|

Area

%

|

Size

um

|

15~20℃

|

700℃

|

|

HSS Rolls

|

10~20

|

<100

|

650~750

|

320

|

80~90

|

700~900

|

2500~3000

|

25~28

|

4~5

|

|

HCI Rolls

|

20~30

|

100~150

|

450~550

|

300

|

70~80

|

600~800

|

1800~2200

|

21~34

|

2~2.5

|

|

ICDP Rolls

|

30~40

|

200~500

|

430~600

|

200

|

75~85

|

400~600

|

2000~2500

|

18~25

|

1

|

|